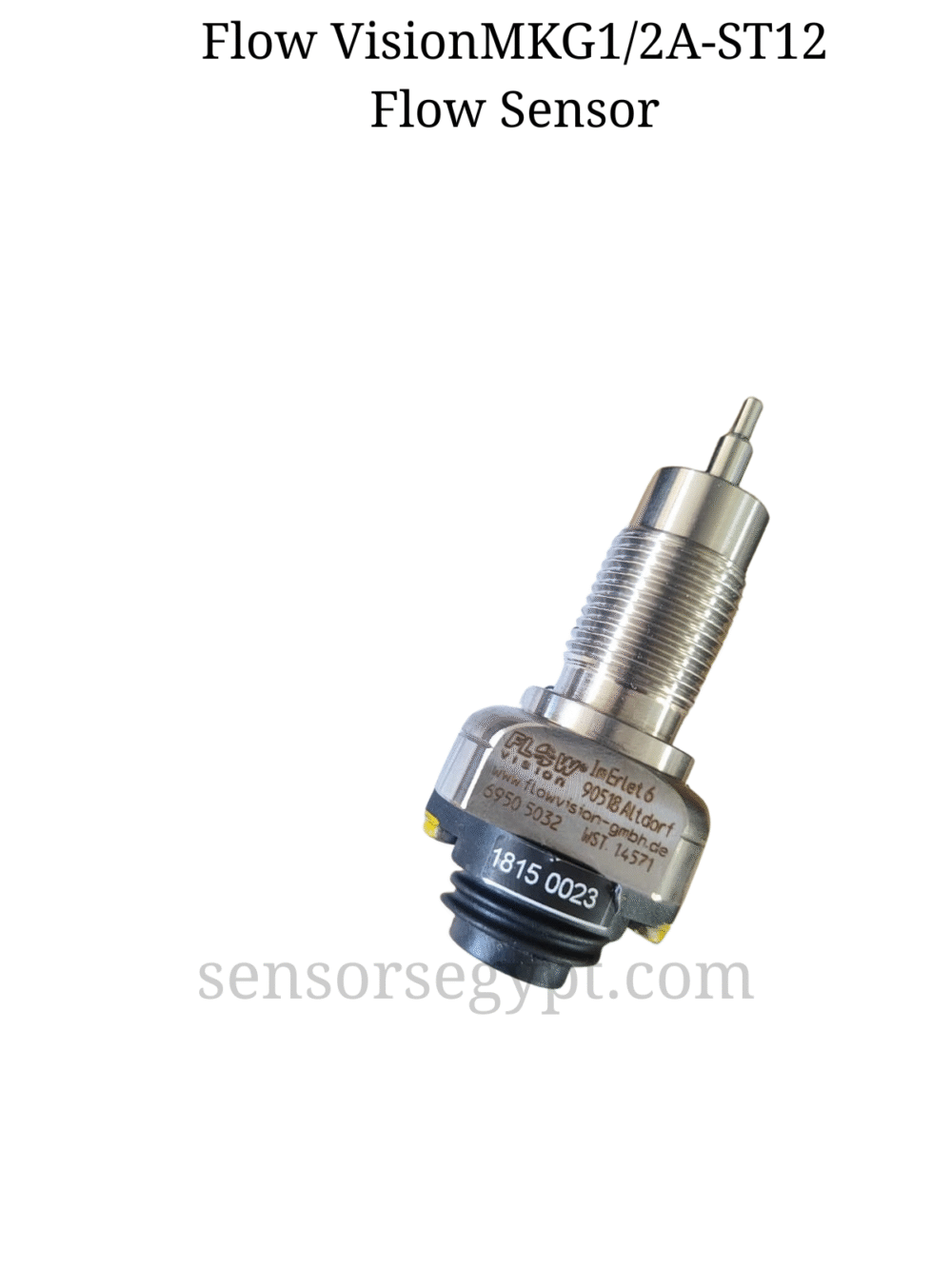

Flow Vision Compact Flow Sensor

Model: MKG1/2A-ST12

VK-No (Order Code): M01001

Manufacturer: Flow Vision GmbH (Germany)

1. General Description

The Flow Vision MKG1/2A-ST12 is a compact, thermodynamic (calorimetric) flow sensor designed for monitoring the flow of liquid media in industrial pipelines.

It operates on the thermal principle (no moving parts), making it highly resistant to wear and insensitive to dirt or solids in the medium. The sensor head is constructed from high-grade stainless steel (1.4571 / 316Ti), ensuring excellent corrosion resistance and suitability for aggressive media. It is designed to be screwed directly into the process pipe via a G 1/2″ thread.

Key Features 🎯

-

No Moving Parts: Wear-free operation due to calorimetric (thermal) monitoring principle.

-

High-Grade Material: Wetted parts made of Stainless Steel 1.4571 (316Ti).

-

Compact Design: Integrated sensor and connection in a single stainless steel probe.

-

Standard Connection: Features an M12 plug (ST12) for quick and secure electrical connection.

-

Robust: High pressure resistance and durability against harsh environments.

2. Technical Specifications

Mechanical & Process Data

| Parameter | Value |

| Process Connection | G 1/2 A (Cylindrical External Thread) |

| Sensor Material | Stainless Steel 1.4571 (AISI 316Ti) |

| Pressure Rating | Typically 100 bar (Standard for MKG series) |

| Medium Temperature | -20 … +80 °C (Typical range) |

| Sensor Length | Standard compact probe length |

Electrical Data

| Parameter | Value |

| Electrical Connection | M12 Connector (4-pin) |

| Supply Voltage | Typically 24 V DC |

| Output | Transistor (PNP) or Relay (depending on specific electronics connected or internal configuration) |

| Protection Class | IP67 (when connector is mated) |

3. Model Code Decoding

Based on the label MKG1/2A-ST12:

-

MKG: Compact Flow Monitor / Sensor Series.

-

1/2A: Process connection G 1/2″ External Thread (Außengewinde).

-

ST12: Electrical connection via M12 Plug (Stecker).

4. Wiring (Standard M12)

While specific wiring depends on whether this is a passive probe or has integrated electronics, standard Flow Vision M12 sensors typically follow this pinout:

-

Pin 1 (Brown): +24V DC

-

Pin 3 (Blue): 0V / GND

-

Pin 4 (Black): Switching Output (Flow Signal)

-

Pin 2 (White): Often used for programming or auxiliary function.

5. Typical Applications

-

Cooling water circulation monitoring (welding robots, injection molding).

-

Pump dry-run protection.

-

Filter monitoring.

-

General flow monitoring in hydraulic and lubrication systems.

Reviews

There are no reviews yet.